Kubota PTO Won’t Engage? How to Troubleshoot the Problem

⚠️ CRITICAL SAFETY NOTICE: Always shut off engine, engage parking brake, and disconnect implements before troubleshooting PTO systems.

🎯 Quick Problem Solver

Most Common Cause: Low hydraulic fluid accounts for 35% of all PTO engagement failures in Kubota tractors. Check your hydraulic fluid level first before diving into complex diagnostics.

Understanding PTO Engagement Problems

When your Kubota PTO shaft won’t engage, you’re dealing with one of the most frustrating yet common tractor issues. The Power Take-Off system is crucial for operating implements, and understanding the root causes can save you hours of downtime and expensive service calls.

Independent PTO Systems

- PTO shaft remains stationary despite switch activation

- Dashboard indicator light stays on

- Engine revs but no power transmission

- Intermittent engagement followed by sudden failure

Transmission-Driven PTO

- Lever won’t engage when clutch is depressed

- Grinding resistance during engagement

- Lever moves freely but shaft doesn’t rotate

- Partial engagement with slipping under load

🛡️ Essential Safety Protocols

- Complete Engine Shutdown: Turn off engine and engage parking brake

- Implement Disconnection: Disconnect all PTO-driven implements

- Area Clearance: Ensure work area is clear of personnel

- Personal Protection: Wear safety glasses and protective equipment

🔍 Systematic Root Cause Analysis

1. Hydraulic System Failures (Most Common)

Primary Issue: Low hydraulic fluid causes 35% of all PTO engagement problems. Hydraulic systems require adequate pressure and volume for proper clutch engagement.

Diagnostic Steps:

- Fluid Level Check: Use dipstick or sight gauge to verify minimum levels.

- Pressure Testing: Test system pressure with hydraulic gauge

- Fluid Quality Assessment: Check for contamination or degraded properties. Overheating?

- Leak Detection: Inspect lines and seals for pressure loss

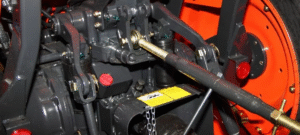

2. Mechanical Linkage Problems

Common on Transmission-Driven PTO: BX1500D case study revealed sheared pins in linkage assemblies as frequent failure points.

Inspection Points:

- Sheared pins or bolts in engagement shaft connections

- Bent linkage rods preventing full travel

- Seized mechanisms requiring lubrication

- Worn bushings causing excessive play

3. Electrical System Malfunctions

M105X Case Study: Blown 5A PTO solenoid fuse caused immediate shutdown with dashboard light remaining illuminated.

Testing Protocol:

- Switch Testing: Use multimeter for continuity verification

- Fuse Inspection: Check all PTO-related fuses

- Safety Sensor Check: Test clutch pedal safety switch

- Solenoid Circuit Analysis: Measure resistance and voltage supply

🔧 Advanced Troubleshooting Procedures

Environmental Contamination Issues

Agricultural environments create unique challenges for PTO systems. Even small obstructions can significantly impact performance:

Debris AccumulationMud, grass, and crop residue can wrap around shafts or block engagement mechanisms

Moisture DamageElectrical components suffer corrosion from agricultural environments

Temperature EffectsExtreme temperatures affect hydraulic fluid viscosity and performance

Clutch Assembly Inspection

Professional-level diagnosis may require PTO cover removal following manufacturer specifications:

Warning Signs Requiring Clutch Replacement:

- Worn friction plates or damaged springs

- Scoring or heat discoloration on clutch plates

- Metal debris indicating internal component failure

💰 Professional Service vs. DIY Repair

DIY Repairs

- Fuse replacement: $5-15

- Switch replacement: $45-85

- Fluid service: $25-50

- Linkage lubrication: Under $20

Professional Service

- Clutch pack replacement: $300-800

- Complete PTO rebuild: $1,200-2,500

- Internal transmission repairs

- Warranty-covered components

🛠️ Model-Specific Troubleshooting

BX Series Tractors

Compact design requires careful access planning. Common issues include PTO selector lever problems and engagement lever binding. Simplified hydraulic systems are typically easier to diagnose than larger models.

M Series Tractors

More complex electrical systems with advanced safety interlocks. Higher hydraulic pressures require professional testing equipment. Electronic control modules can create multiple symptom presentations.

L Series Tractors

HST models require specific clutch safety switch verification procedures. Mid-range complexity balances serviceability with performance. Common transmission-driven PTO linkage issues.

🔄 Prevention and Maintenance Schedule

Monthly Maintenance

- Check hydraulic fluid level and condition

- Inspect PTO shaft and safety guards

- Clean electrical connections

- Lubricate mechanical linkages

Seasonal Service

- Complete hydraulic system service

- PTO clutch adjustment verification

- Comprehensive electrical system testing

- Replace wear items per manufacturer schedule

🚫 Common Troubleshooting Mistakes to Avoid

Critical Errors That Worsen Problems

Forcing Engagement: Never force a stuck PTO lever or continue operating when engagement feels abnormal. This can shear internal pins, damage clutch plates, or cause expensive transmission damage. If resistance is encountered, stop immediately and investigate the root cause.

Ignoring Safety Interlocks: Bypassing safety switches to “get the job done” creates serious hazards and often masks underlying problems. Modern Kubota tractors have multiple safety systems that prevent PTO engagement under unsafe conditions – these exist for operator protection and equipment longevity.

Using Wrong Hydraulic Fluid: Universal hydraulic fluids may seem cost-effective, but Kubota-specific formulations ensure optimal performance. Wrong viscosity grades can cause slow engagement, premature wear, and temperature-related failures. Always consult your owner’s manual for proper fluid specifications.

Neglecting Seasonal Adjustments: PTO systems require different maintenance approaches based on operating conditions. Cold weather operation demands thinner hydraulic fluids and extended warm-up periods, while hot summer conditions require more frequent fluid changes and cooling system maintenance.

🔄 Seasonal Operating Considerations

Winter Operations

- Allow extended warm-up periods for hydraulic fluid

- Check for ice formation in electrical connections

- Monitor fluid viscosity in extreme cold conditions

- Inspect for frost damage on exposed components

Summer Operations

- Monitor hydraulic fluid temperature during heavy use

- Increase cooling system maintenance frequency

- Check for heat-related electrical component failure

- Clean debris from cooling fins more frequently

Replacement Parts and Sourcing Strategy

When PTO repairs become necessary, parts quality significantly impacts long-term reliability. Genuine Kubota parts ensure proper fitment and performance, though aftermarket alternatives exist for budget-conscious operators.

Essential Spare Parts Inventory

Maintain inventory of commonly failed components to minimize downtime: PTO fuses (5A and 10A ratings), hydraulic fluid (2-3 quarts), PTO engagement switch, basic linkage pins and bushings. These items represent 80% of field-repairable PTO failures and can save costly service calls during critical operating periods.

🎯 Key Takeaways

Kubota PTO engagement failures typically result from identifiable root causes that respond to systematic troubleshooting. The majority of issues stem from hydraulic fluid problems, mechanical linkage failures, or electrical system malfunctions. Regular maintenance and proper operating procedures represent the most cost-effective approach to preventing PTO engagement failures, ultimately maximizing equipment reliability and operational efficiency.

❓ Frequently Asked Questions

Why won’t my Kubota PTO engage even though the switch is on?

The most common cause is low hydraulic fluid, accounting for 35% of engagement problems. Check your hydraulic fluid level first, then inspect electrical connections and fuses. Safety interlocks may also prevent engagement if the clutch pedal isn’t fully depressed or the operator isn’t properly seated.

What should I do if my PTO lever feels loose and floppy?

This typically indicates mechanical linkage failure, often a sheared pin connecting the lever to the engagement shaft. Inspect the linkage assembly for broken or missing pins, bent rods, or worn bushings. This is a common issue in older Kubota models requiring linkage repair or replacement.

Can I troubleshoot PTO problems myself or do I need a mechanic?

Basic troubleshooting like checking fluid levels, inspecting fuses, and testing switches can be done by most operators. However, internal transmission repairs, clutch pack replacement, and hydraulic system rebuilds require professional expertise and specialized tools. Simple repairs cost $5-85, while major repairs range from $300-2,500.

How often should I service my Kubota PTO system?

Perform monthly checks of hydraulic fluid levels, PTO shaft condition, and electrical connections. Schedule seasonal comprehensive service including hydraulic system maintenance, clutch adjustments, and complete electrical testing. Regular maintenance prevents 70% of common PTO engagement failures.

Check us out for more expert tractor repair guides at TractorPartsCentral.com