Understanding Your Kubota’s Operator Presence System (OPS)

What is the Kubota Operator Presence System?

Core Safety Functions

The OPS performs several life-saving safety functions that have revolutionized tractor safety across the agricultural industry:

Engine Shutdown Protection – Completely shuts down the engine if you leave the seat while the tractor is moving or implements are engaged

PTO Disengagement – Automatically stops rotating implements when no operator presence is detected

Hydraulic System Lockout – Disables loader arms, three-point hitches, and hydraulic implements

Movement Prevention – Stops the tractor from moving by disabling transmission or applying parking brakes

How Your OPS Works

The Seat Switch Mechanism

– Operating weight threshold: 80-100 pounds

– Response time: Instantaneous engagement, 0.5-2 second delay for disengagement

– Electrical specs: 12V DC with low amperage switching

– Switch type: Normally open, closes when activated

The foundation of your OPS is the seat switch located directly beneath your operator seat. This spring-loaded mechanism responds to your weight and presence, closing a circuit that signals to the tractor’s control system when sufficient weight is applied. The switch is engineered to withstand thousands of activation cycles while maintaining precise calibration for consistent safety performance.

Integration with Tractor Systems

Modern Kubota tractors integrate the OPS with multiple vehicle systems through a centralized Electronic Control Module (ECM). This creates a comprehensive safety network connecting:

Engine management system

Transmission controls

PTO engagement mechanisms

Hydraulic control valves

Dashboard warning systems

The integration allows for intelligent decision-making based on operating conditions, providing graduated responses rather than simply shutting everything down immediately.

Common Problems and Symptoms

Starting Issues

Symptom: Tractor fails to crank or start despite proper key position and adequate battery power.

Root Causes:

Corroded or damaged seat switch contacts

Misaligned seat switch mounting brackets

Broken or loose wiring connections

Insufficient operator weight to activate switch

Switch calibration drift over time

Environmental factors such as moisture infiltration, temperature extremes, and vibration from normal operation can gradually degrade switch performance, leading to intermittent or complete failure.

PTO-Related Malfunctions

Symptom: Engine runs normally until you engage the PTO, then immediately shuts down. PTO won’t Engage?

Diagnostic Indicators:

Engine runs fine in neutral with PTO disengaged

Immediate shutdown upon PTO lever movement

Dashboard warning lights illuminate before shutdown

Normal restart after returning PTO lever to neutral

Movement and Hydraulic Problems

Symptom: Engine runs normally but tractor won’t move, hydraulics operate weakly or not at all.

This safety feature prevents runaway tractors but can be frustrating when caused by faulty sensors detecting false operator absence. Understanding the system logic helps diagnose whether the issue is mechanical, electrical, or calibration-related.

Testing and Diagnostic Procedures

Visual Inspection Protocol

✓ Switch housing for cracks or damage

✓ Actuator arm for proper movement and alignment

✓ Mounting brackets for looseness or damage

✓ Wiring connections for corrosion or looseness

✓ Seat cushion integrity affecting weight distribution

Electrical Testing Methods

Using a digital multimeter, test the seat switch for proper electrical function:

Testing Parameters:

Open circuit resistance: >1 MΩ (megohm)

Closed circuit resistance: <1 Ω (ohm)

Operating voltage: 12V DC nominal

Current draw: <0.5 amp during switching

⚠️ CRITICAL SAFETY WARNING

Adjustment and Replacement Procedures

Seat Switch Adjustment Techniques

Many OPS problems can be resolved through proper adjustment rather than component replacement:

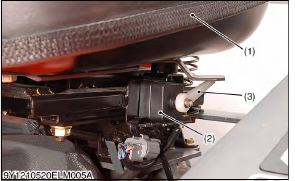

1. Locate seat switch mounting bracket under seat pivot

2. Loosen mounting bolts slightly (don’t remove completely)

3. With operator seated, adjust bracket for firm switch contact

4. Verify consistent actuation through full seat range

5. Tighten bolts to specification (15-20 ft-lbs)

6. Test operation thoroughly

Switch Replacement Process

When replacement is necessary, use only genuine Kubota OPS switches or approved equivalents meeting original specifications.

Average Replacement Costs:

Seat switch replacement: $75-$150 (parts and labor)

Wiring harness repair: $125-$300

Complete system overhaul: $500-$1,200

Model-Specific Considerations

B-Series Tractors

Incorporate multiple interconnected safety switches including seat, PTO, rocker pedal, and transmission switches. All must be in proper positions for starting.

L-Series Tractors

Feature more sophisticated OPS with dual wiring runs for redundancy and enhanced hydraulic safety lockouts.

BX-Series Tractors

May require PTO lever sensitivity adjustments through tab bending for better engagement consistency.

Prevention and Maintenance Best Practices

Preventive Maintenance Schedule

Monthly: Visual inspection of connections and wiring

Quarterly: Electrical contact cleaning and tightening

Annually: Complete electrical system testing and documentation

As needed: Environmental protection improvements

Regular maintenance not only prevents costly failures but also ensures the system responds reliably in emergency situations where split-second activation could prevent serious injury or death.

Key Takeaways

The Kubota Operator Presence System is a critical safety technology that has significantly reduced tractor-related accidents. Understanding its function, recognizing common problems, and maintaining it properly ensures both safety and operational efficiency. Never permanently disable safety systems – the protection they provide far outweighs any temporary inconvenience.

Frequently Asked Questions

Why won’t my Kubota tractor start even though the battery is good?

The most common cause is a faulty or misadjusted seat switch in the Operator Presence System. The OPS prevents starting if it doesn’t detect proper operator presence. Check that you’re fully seated and the seat switch is making proper contact.

Can I bypass the OPS if it’s malfunctioning?

Only qualified technicians should perform temporary diagnostic bypassing for troubleshooting purposes. Never permanently disable the OPS as it’s a critical safety system designed to prevent serious accidents and fatalities.

How often should I maintain my OPS system?

Perform visual inspections monthly, clean electrical contacts quarterly, and have complete system testing done annually. This preventive maintenance typically costs $100-200 per year but prevents expensive emergency repairs.

What’s the average cost to repair a faulty OPS?

Basic seat switch replacement costs $75-150, while more complex wiring repairs range from $125-300. Complete system overhauls can cost $500-1,200, but this is rare with proper maintenance.

Check us out for more expert tractor maintenance guides at TractorPartsCentral.com